Target Group SAP PP User and IT Professionals

Summary

The BOM Browser with Master Data Check got even better 🙂

Content

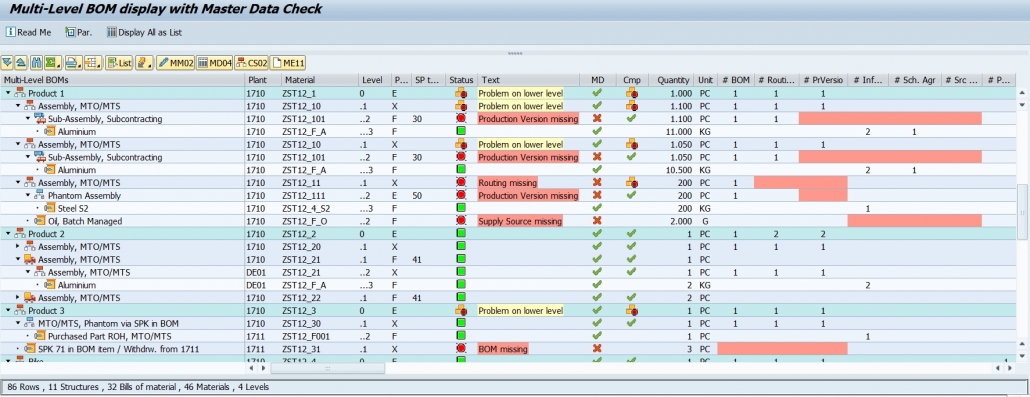

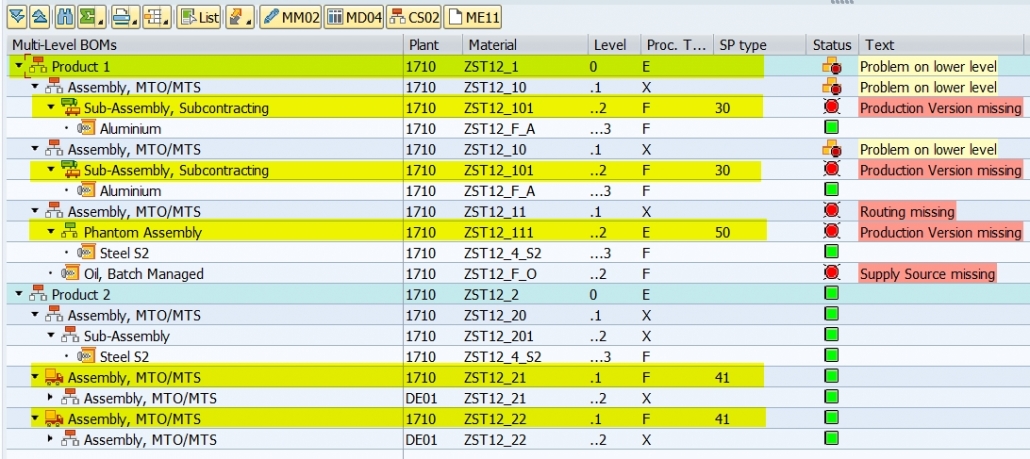

My Add-On BOM Browser with Master Data Check meats considerable customer demand and I implemented enhancements:

- Multi-plant selection

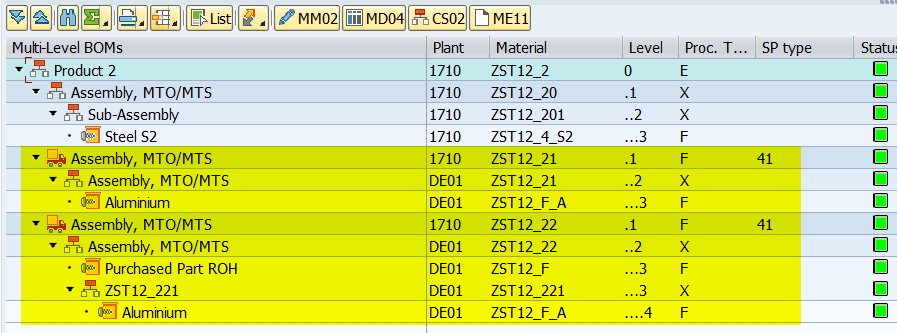

- Optional cross-plant BOM explosion. Stock-transfer via special procurement key is treated similar to an extra BOM level. The BOM explosion proceeds in the supplying plant.

- Display plant stock

- Visualization of phantom assemblies, subcontracting, stock transfer and regular in-house production with icons

- MRP Area specific BOM explosion via production version determination and storage location determination

- Separate counters for WM control cycles and Kanban control cycles

- Additional report for material evaluation with master data check without BOM explosion. This report contains more material data and is ideal for fast and flexible material evaluation with focus on checking PP/MM master data and viewing material details.

- Settings for reaction on missing production version or source list: Error, Warning or No Reaction

You find more info here.

I’m looking forward to comments and questions.

Do the SAP standard transactions for mass evaluation of BOMs satisfy your requirements?

How robust is your workflow for creation and maintenance of materials and related master data for production and procurement? How useful would be a mass evaluation of materials with existence information (in form of counters) for assigned master date (routings, BOMs, source list, infor records, control cycles, production versions) for you?

Would you see the benefit of using the BOM Browser with master data check mainly in

- Master Data Mangement for checking existence of critical master data?

- In Product Costing for viewing multi-level BOM structures across plants, with plant stock and valuation data?

- In Logistics, e.g. for monitoring stock in BOM structures or checking existence of WM or Kanban control cycles?

- In Production Planning as an overview of BOM structures with stock and MRP parameteres. Maybe enhanced with coverage data or summarized requirements and receipt

Do you have ideas for other use cases or improvements?